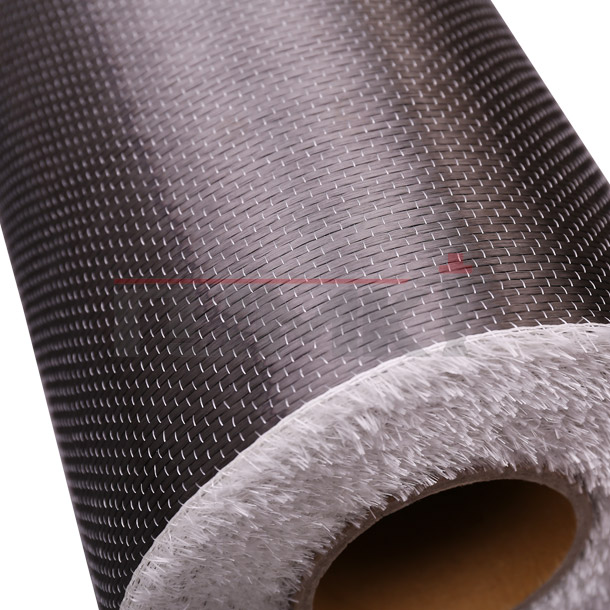

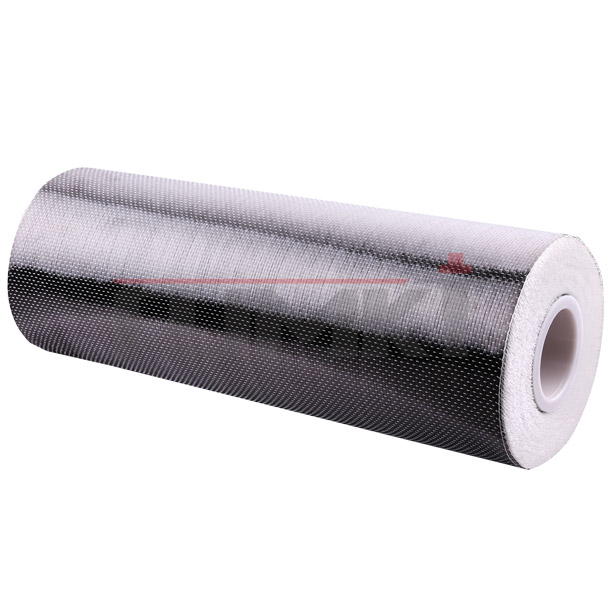

NJMKT carbon fiber sheet is a kind of unidirectional carbon fiber reinforced material made by imported Toray carbon fiber filament. It has two kinds of thickness of 0.111mm (200g) and 0.167mm (300g), and many kinds of width: 100mm, 150mm, 200mm, 300mm, 500mm and other special width requirements, widely used for tensile and seismic reinforcement of structural components. And it can be regarded as carbon fiber composite material when used with NJMKT-carbon fiber impregnation adhesive, which is suitable for reinforcement of concrete and wood structure, and has reached the requirements of "Reinforced Concrete Structure Design Code GB50367-2013", This product can effectively improve bearing capacity of components, seismic performance and durability.

Key Features

1.Light weight, easy for construction, low density, 23% of steel material, no increase of self-weight or section size to components

2. This flexible sheet can easily be cut according to your desired shape and have close adhesion with reinforced concrete surface, suitable for extensive shape structures

3. Small thickness, easy to overlap, excellent performance of winding and wrapping for various types of reinforcement, such as curved surface, strange-shape components, etc.

4. High tensile strength and flexibility, it can achieve the same effect of reinforced steel plate

5. Anti-acid and alkali, corrosion resistance, suitable for any harsh environment

6. The matching epoxy resin adhesive (suggested our factory manufactured carbon fiber impregnating adhesive) has good permeability, easy installation and short construction period

7. Non-toxic, non-irritating odor, environmentally safe, operation can be done in living situation

8. High tensile strength of 4-8 times of ordinary steel

NJMKT Carbon Fiber Sheet PK inferior sheet

1. Imported carbon fiber filament, excellent smoothness, easily to be cut according to your desired shape regularly

2. High tensile strength of 4-8 times of ordinary steel

3. Anti-acid and alkali, corrosion resistance, suitable for any harsh environment

4. Excellent performance of winding and wrapping for various types of reinforcement, such as curved surface, strange-shape components, etc.

5. Light weight, low density, 23% of steel material, no increase of self-weight or section size to components

It is your outstanding option to deal with the following engineering problems:

1. Increasing building service load

2. Changing usage function of engineering projects

3. Material aging

4. Concrete strength grade is lower than the design value

5. Structural cracks treatment

6. Repair and protection for in-service components in harsh environment

7. Improve seismic performance of buildings in multiple seismic area

8. Rreinforcement and repair of concrete structures because of disasters suffering and durability

9. Deficiency of concrete rebars

10. Building reinforcement and retrofit project

11.Building crack leakage

12.Chimney and coal mine reinforcement

13.Other applications: satellites, aircraft, sports, industrial products and many other reinforcement fields

Construction Process:

1. Surface treatment: Clean and abrade the surface of base material comprehensively to make sure there is not any attachment, if the paste parts have sharp edge, it should be abraded to soft round shape of a minimum radius of 20 mm. As the aim to use NJMKT-carbon fiber sheet is to improve the structural members, so the status of base surface should be paid attention to make sure that it could transfer load ability from the sheet to the structure surface.

2. Rollcoat epoxy resin adhesive and repair the rough surface (recommend to use surface leveling adhesive of our company), then mark the ink lines.

3. Rollcoat epoxy resin adhesive (recommend to use matching epoxy resin impregnation adhesive of our company) to the bonding surface, the adhesive must be used full enough.

4. Bond carbon fiber sheet which had been cut into suitable size to base material surface coating of adhesive, the sheet should be straight, extended. (If overlapping, the length of lap joints should be 20mm and the joints should not be in the middle but 1/3 of base material)

5. Re-rollcoat impregnation adhesive to the surface of carbon fiber sheet to ensure complete coverage of the surface of sheet and full impregnation of the fiber.

6. Use hard rubber stick or plastic scraper to roll and compact carbon fiber sheet repeatedly to keep it straight, extended, no bubbles, full penetration.

7. Rollcoat again the adhesive to soak and use scraper to scrape and de-bubble repeatedly.

8. Finally, sprinkle 3-6 mm sand (quartz sand) on adhesive-coated surface to make sure the adhesion of mortar cover.

Installation flow chart

1.Surface treatment

2.Rollcoat epoxy resin adhesive

3.Repair rough surface

4.Mark ink lines

5.Rollcoat impregnation adhesive

6.Bond carbon fiber sheet

7.Rollcoat & permeate

8.De-bubble

9.Rollcoat impregnation adhesive

10.Rollcoat & permeate

11.De-bubble

12.Sprinkle quartz sand

13.Finish

Factory capability

NJMKT has our own product quality testing center and a full range of imported internationally-advanced testing equipment which is comparable with national testing center. We promise to test all materials before manufacture, only when the testing data meets the requirement, we put into production operation.

1.On-site production of carbon fiber sheet

2.Strict automatic unloading system per 100m to be off production line

3.Refuse short, narrow, insufficient materials

4.Standard specification, easily cut

Storage:

100m/roll

Carbon fiber sheet should be stored in dry and well-ventilated place and protect from sunlight.

Standard: GB50367-2013, GB50728-2011

NJMKT promises to meet the technical requirements of the following GB50367-2013 "Design code for concrete structure reinforcement" and GB50728-2011 "Technical code for safety identification of reinforcement materials for engineering structures".

| Test item | High - strength Grade Ⅰ | High - strength Grade Ⅱ | High - strength Grade Ⅲ | |

| Standard value of tensile strength (MPa) | ≥ 3400 | ≥ 3000 | ≥ 1800 | |

| Tensile modulus of elasticity (MPa) | ≥ 2.3×105 | ≥ 2.0×105 | ≥ 1.8 × 105 | |

| Elongation at break (%) | ≥ 1.6 | ≥ 1.5 | ≥ 1.3 | |

| Bending strength (MPa) | ≥ 700 | ≥ 600 | ≥ 500 | |

| Interlaminar shear strength (MPa) | ≥ 45 | ≥ 35 | ≥ 30 | |

| Positive bonding strength of fiber composite material and base material (MPa) | ≥ 2.5, cohesive failure of concrete | |||

| Brand of NJMKT sheet | MKT | XK | AN | |

| Carbon filament type | T-700-12K | T-36-12K | T-35-12K | |

| Test item | Standard requirement of high - strength Grade Ⅰ | Test Result | Single item assessment |

| Standard value of tensile strength (MPa) | ≥ 3400 | 3422 | Qualified |

| Tensile modulus of elasticity (MPa) | ≥ 2.3 × 105 | 2.41 × 105 | Qualified |

| Elongation at break (%) | ≥ 1.6 | 1.7 | Qualified |

| Bending strength (MPa) | ≥ 700 | 837 | Qualified |

| Interlaminar shear strength (MPa) | ≥ 45 | 52 | Qualified |

| Positive bonding strength of fiber composite material and base material (MPa) | To concrete and base material: ≥ 2.5, and base material cohesive failure | 3.5, and base material cohesive failure | Qualified |